OFPSI’s new AeroProtect™ masking films and coatings will revolutionize the way aircraft interior production teams cover and protect components and fixtures, significantly cutting the time and labor required for conventional wrapping and taping techniques.

The low VOC water-based coatings and films protect in ways that conventional techniques cannot, and remove with less effort and lower risk of damage from residue or aggressive adhesives.

AeroProtect is a unique innovation that permits recently finished surfaces to “breathe” or off-gas and cure normally while shielded from incidental damage. Protection that prevents this air flow can cause impurities in finishes that require stripping and rework.

AeroProtect spray comes in two basic formulas: AeroProtect Pro and AeroProtect Pro Plus. Both cover and protect without adhesives and can be easily removed with no residue or effect on objects covered with one exception. AeroProtect Pro cannot be used with polycarbonate surfaces such as Plexiglas® and Lucite® and similar materials like Lexan®, Tuffak®, Makrolon® and Polygal® because the molecular properties of surface and coating may cause permanent binding over time. For these materials, AeroProtect Pro Plus can be used and safely and easily removed from aircraft windows, windshields, mirrors and similar components.

Liquid Protection

Liquid Protection

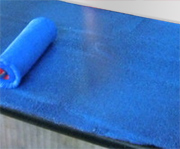

Easily applied AeroProtect in liquid form reduces labor time and costs substantially over traditional protection methods because it can be painted or sprayed onto cabinets, tables, paneling and other aircraft components. Soon after application, AeroProtect Pro dries to a blue tinted (or optionally, clear) resilient flexible vinyl film coating. AeroProtect Pro Plus is tinted green so each formula can be identified.

Once applied, AeroProtect shields surfaces against dust, scratches, marks, spills and general wear. Workers can actually write on protected surfaces without consequence. When the job is complete, AeroProtect peels off by hand with little effort and zero residue.

Durable, Flexible Film

The same AeroProtect defenses are also available in translucent, malleable protective films for applications where painting and spraying are not practical, such as items already installed in the aircraft where adjacent surfaces could be jeopardized by overspray.

One of the films, AeroProtect for Carpet was specifically designed with the strength to defend wool and wool-blend carpet from heavy foot traffic and dropped items. AeroProtect for Fabric, with somewhat less aggressive adhesive, was created for more delicate fabrics, silk carpeting and vulnerable wall coverings, holding fast in vertical applications. These films have a blue tint but can be ordered without tinting.

A third has no adhesive and was created for safe use on finished surfaces. It includes the patented breathability that permits the off-gassing of painted, stained and sealed cabinetry and woodwork.

All three environmentally friendly films can be easily applied and cleanly removed with little effort and no tools.

Both liquid and film meet highest standards for protection against soiling, wear and accidents. Application requires no tape or fastening and may eliminate patterns and cutting of shapes, saving significant labor and time. An edge or corner of the material can be lifted for underlying access and then effectively re-applied.

AeroProtect can serve for long periods of time and then easily peel away without pulling fibers or leaving any stickiness or residue whatsoever.

AeroProtect could shave significant costs for aircraft manufacturers and completion centers.

AeroProtect can help limit time-on-ground for airline maintenance.

AeroProtect saves money, prevents rework for airline interior suppliers.