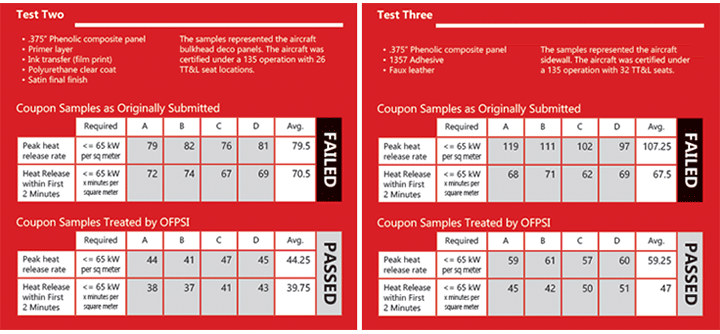

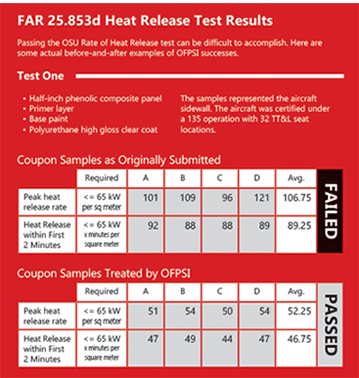

OFPSI has documented procedures for thousands of different material combinations using their flame retardant as a base. They’ve discovered methods that achieved certification for materials that had never before qualified under FAA guidelines. Through thousands of tests, they’ve developed an expertise unique in the industry.

OFPSI has documented procedures for thousands of different material combinations using their flame retardant as a base. They’ve discovered methods that achieved certification for materials that had never before qualified under FAA guidelines. Through thousands of tests, they’ve developed an expertise unique in the industry.

Each material amalgam must be specifically documented as applied but examples of those the company has shepherded through FAA 65/65 burn test approval are:

- composite buildup of .375 to 1 inch honeycomb panel, primer, paint and top coat

- composite buildup of .375 to 1 inch honeycomb panel, primer, base paint, aqua ink transfer film and 3-step clear coat

- synthetic faux leather used in headliners, side walls and linings

- genuine leather bonded to composite phenolic panels using a contact adhesive

- fiberglass parts for interior fabrication and mechanical system ducting

- numerous brands and coats of mixed paints and sealants

To date, OFPSI has reversed failures, limited disruption of production schedules and capped losses on dozens of projects, preserving tens of thousands of dollars in completion center profits. With years in service and thousands of flight hours, OFPSI has had no complaints filed for reduced performance or side effects on treated materials.